Specifications

KCE® SiSiC/RBSiC Technical Data Sheet

| Technical Parameters | Unit | Value |

| Silicon Carbide content | % | 85 |

| Free Silicon content | % | 15 |

| Bulk Density 20°C | g/cm³ | ≥3.02 |

| Open Porosity | Vol % | 0 |

| Hardness HK | kg/mm² | 2600 |

| Flexural Strength 20°C | MPa | 250 |

| Flexural Strength 1200°C | MPa | 280 |

| 20 – 1000°C (Coefficient of Thermal Expansion) | 10–6 K–1 | 4.5 |

| Thermal Conductivity 1000°C | W/m.K | 45 |

| Static 20°C(Modulus of Elasticity ) | GPa | 330 |

| Working temperature | °C | 1300 |

| Max. Service Temp (air) | °C | 1380 |

Applications

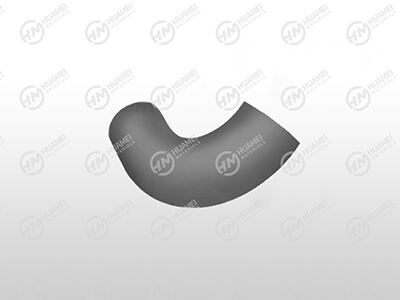

KCE® RBSiC/SiSiC Silicon carbide wear-resistant linings/liners feature characteristics such as wear resistance, high-temperature resistance, high hardness, impact resistance, and corrosion resistance against acids and alkalis. Their actual service life exceeds that of polyurethane materials by more than 7 times and that of alumina materials by over 5 times. These linings are particularly suitable for industries involving strong corrosion, coarse particle material classification, concentration, and dehydration in mineral processing and mixing sectors. They are also widely used in coal, water conservancy, and petroleum extraction industries. Examples include silicon carbide ceramic cones, elbows, bends, tees, arc plate patches, linings, and cyclone liners, making them especially ideal for the mineral processing industry.

Advantages

With the transformation and upgrading of the manufacturing industry and the advancement of technology, the demand for the application of silicon carbide pipe linings/liners continues to grow, and their advantages in separation efficiency, wear resistance, energy consumption reduction, and easy maintenance are becoming increasingly prominent.